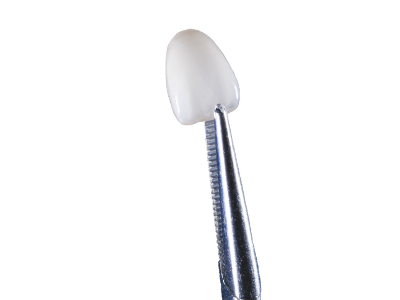

Zirconia Veneers

Zirconia Veneers by SCD combine strength, lifelike aesthetics, and superior bonding to deliver exceptional patient results.

View Product

IPS e.max® (CAD) |

|

|---|---|

| Material | Lithium Disilicate (Able to be layered) |

| Aesthetics | ✓ ✓ ✓ ✓ ✓ |

| Indications | Crowns Inlays/Onlays Veneers Bridges (Up to Premolar) |

| Margins | Shoulder |

| Etch | Hydrofluoric Acid |

| Durability | ✓ ✓ ✓ |

| Cementation | Adhesive |

| Bonding | ✓ ✓ ✓ ✓ |

| Flexural Strength | 470 MPa Press - 530 MPa CAD |

| Method of Manufacture | CAD/CAM, Press and Customisation |

| Material Shades/Colouring | 20 Shades |

| Stain Resistance | ✓ ✓ ✓ ✓ |

| Span/Ingot Size | Single Unit to 3-unit Bridges (Anteriors and Premolars Only) |